A combined 190-year history

Humphrey Feeds & Pullets is a family business established by John Humphrey in 1932. Having been pensioned out of the RAF following an injury, he bought North Fields Poultry Farm (still the location of the head office of the group of businesses) at Twyford, Hampshire, from where he set in motion three generations of egg production.

John was quick to realise that he needed to control his own inputs, and so reared his own birds and fed them with his own feed, laying the foundations for the successful poultry feed and pullets business that operates today.

Initially all his birds were free range, but the eggs they produced were seasonal, being only available in the summer - eggs had to be pickled in order for them to ‘keep’ over the winter months. John heard of developments in the US, where birds were housed indoors to create a constant summer, which enabled him to sell eggs all year round.

Humphrey Feeds & Pullets History

1940s

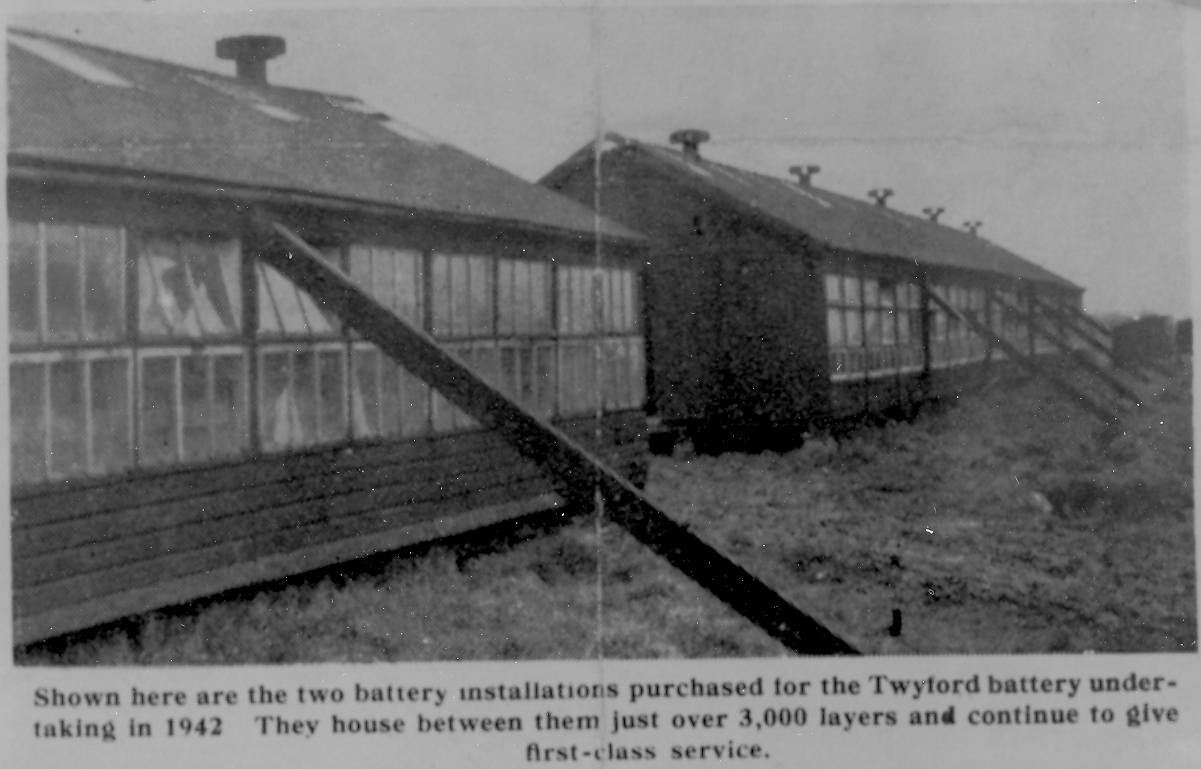

In 1942 two second-hand houses with cages were purchased and although these had to remain empty for most of the war period, eventually they held 2,000 and 1,344 birds respectively.

Mr Humphrey then built three brick houses with corrugated roofing. In all three houses, electric lighting gave laying birds a 14 – hour day. The birds’ performance was individually recorded on paper sheets stuck to the front of the top tier mash troughs which were at a suitable height for writing.

Besides being a large-scale producer of commercial eggs – up to 120 cases a week were collected by the packing station – John Humphrey was an accredited breeder with 2,000 head of breeding stock.

1950s – 70s

The main farm, covered 55 acres of land, which was large enough for rearing, breeding and laying stock (you would never put those three enterprises on the one site today!). Grass was the only crop grown and every blade of it was utilised for the poultry. Part of the grass was grazed by the birds with a cut taken at the end of April and delivered to the grass dryer on the farm. Each year five acres of grassland was ploughed, allowed to lie fallow during the summer and then re-seeded in the autumn. The grass was cut up to a further 5 times during the season and then stored in hay-box units.

The grass meal produced from the dryer was incorporated in the layers mash produced in the feed mill developed in one end of a timber building which had been converted for the purpose. The feed manufacturing equipment consisted of the hammer mill, a 1 ton mixer and three Crittall silos. There was a concrete pit into which up to 12 tonne of grain could be stored from the delivery lorry before elevating into the silos – how things have changed today!

John had always wanted to control his key inputs: rearing his own birds, and fed his own feed. Initially he bought a concentrate from Silcock to add to the main raw materials, but in the 1960s the mill was significantly upgraded to allow complete feeds to be manufactured from materials purchased and milled on site, dispensing with buying in concentrates. Feed was delivered to the growing number of farms by tractor, until 1971 when the first lorry was purchased.

1980s – 90s

More HGV’s were jointly bought to supply rearing and laying feed to friends. In 1984 a modern new mill was commissioned. This remains a ‘cutting edge’ plant, designed specifically to manufacture poultry mash. In 1991 a further enhancement was the installation of a pelleting plant which, along with a mash cooling capability, was designed to address the then recent bio-security issues raised by Edwina Curry – this mill was labelled by Feed International as ‘The 21st Century Feed Mill’.

The pelleting plant originally supplied feed to broiler producers across the south of England, but that market has changed, allowing the business to focus on the growing number of free range egg producers, and the manufacture of organic feeds.

We continue to invest in the feed business, spending £1 million in the last 3 years alone. We continue to develop and refine the plant to ensure that our offer to customers meets their requirements. Our key area of expertise is producing optimal grists for poultry. We have a specially developed computer controlled grinder which allows us to custom make up to 18 different grists for different types of poultry – consistently.

2000s

Our organic poultry feeds have consistent, proven performance benefits; nurturing optimal performance from layers and broilers through careful use of organic raw materials.

Humphrey Feeds became part of the Wynnstay Group in 2022, and in 2023 combined with the Wynnstay poultry team to become Wynnstay Humphrey Feeds & Pullets. We continue to see a good future for our approach of uncompromised nutrition, experienced service and a flexible approach to customers – giving them what they want – cost effective feed and advice.

Wynnstay Group Plc History

Our timeline and history can be found on our Group website.

....Tel..Ffôn....: 01962 764 523

....Email..E-bost....: enquiries@hfandp.co.uk

Latest poultry knowledge